CDMOs play an increasingly important role in antibody production. Nevertheless, in the world of biopharmaceuticals, the development and manufacturing of drug products is a complex and highly regulated process, which also applies for innovative tools like recombinant antibodies.

This is where CDMOs come in. Contract development and manufacturing organizations (CDMOs) provide a range of services to support the development and production of biologics, including antibodies, for use in a variety of therapies as well as for research and diagnostic applications.

In this article, we will explore the role of CDMOs in the biopharmaceutical industry, specifically focusing on the services they offer for antibody production.

What is the role of contract development and contract manufacturing?

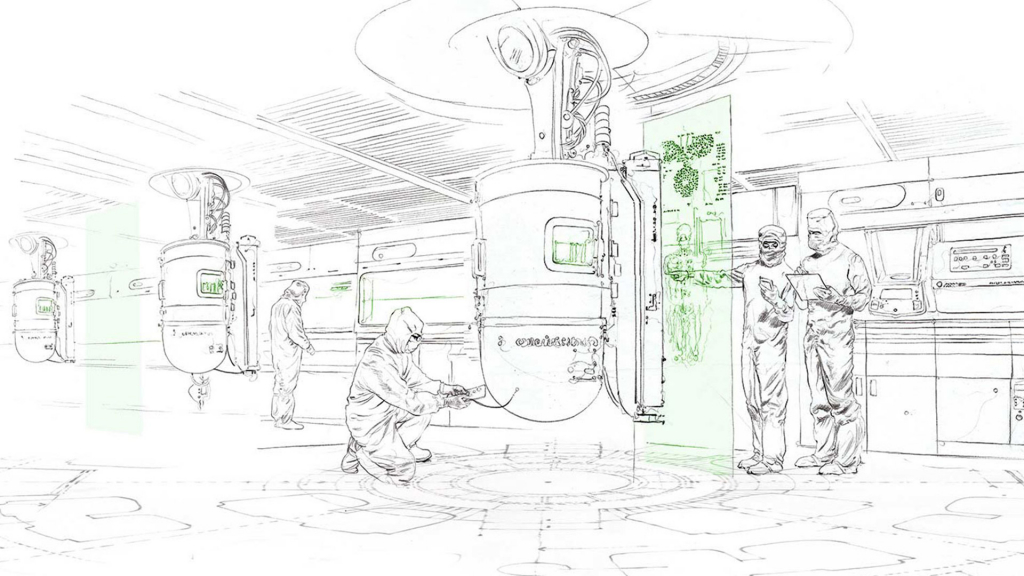

CDMOs play a crucial role in the biopharmaceutical industry by providing end-to-end services for the development and manufacturing of biologics, including monoclonal antibodies (mAbs). They offer a range of services from process development to large-scale manufacturing, enabling pharma and biopharma companies to outsource their manufacturing needs to a specialized contract development and manufacturing organization.

CDMOs have expertise in various aspects of the biologics manufacturing process, such as upstream processes and downstream process development, scale-up, drug substance and antibody production, formulation, and commercial manufacturing. Their experience in recombinant antibody expression, purification, and characterization allows for the efficient and cost-effective production of high-quality biologics for use in clinical trials and commercial manufacturing.

By partnering with a CDMO, biopharmaceutical companies can leverage the expertise and state-of-the-art production facilities of their chosen CDMO partner, freeing up resources to focus on their core competencies such as drug discovery, clinical development, and regulatory affairs. CDMOs provide a range of services to support the entire biologics development process, from early-stage development to commercial manufacturing.

As a trusted CDMO partner, their clients benefit from their established infrastructure, robust quality systems, and compliance with regulatory standards. The CDMO team can handle several aspects of biologics manufacturing, from process optimization to large-scale production, to ensure that their clients’ drug product is of high quality and compliant with regulatory standards as well as tight timelines. In addition, CDMOs may also have experience with gene therapy, which is becoming increasingly important in the field of life sciences.

Services provided by CDMOs

Contract Development and Manufacturing Organizations (CDMOs) offer a range of services for the production of high-quality antibodies. They provide comprehensive services to support the production of antibodies, from target identification to final product release. Their expertise and advanced technologies can help accelerate development in the field of oncology and other therapeutic, diagnostic and research areas.

Antibody Generation / Antibody production

CDMOs can create custom antibodies that specifically target certain proteins or molecules (antigens). This can be achieved through immunization of animals or using phage display technology.

CDMOs can also produce large quantities of antibodies using different expression systems such as bacterial, yeast, or mammalian cell cultures (e.g. CHO cells), with the use of specialized equipment like single-use bioreactors. They can help to streamline the antibody production process and increase product quality and yield.

Read more: In vitro antibody production

Antibody Engineering

CDMOs can modify antibodies to enhance their affinity, specificity, or other properties using techniques such as protein engineering, site-directed mutagenesis, or antibody humanization.

Cell Line Development

CDMOs can develop cell lines suitable for the production of antibodies, ensuring their growth and stability, and optimizing their performance.

Antibody Purification

CDMOs can purify antibodies using various chromatography techniques such as affinity chromatography, ion-exchange chromatography, or size-exclusion chromatography, to ensure high purity and yield.

Antibody Conjugation

CDMOs can conjugate antibodies with different molecules such as fluorescent dyes, enzymes, or drugs to create antibody-drug conjugates (ADCs) or other specialized reagents.

Validation and Characterization

CDMOs can perform various analytical tests to characterize antibodies such as ELISA, Western blotting, or mass spectrometry, to ensure their quality, purity, and potency. They can also develop preclinical assays to support the development of vaccines or antibody drug conjugates (ADCs).

Cell Banking

CDMOs can store and manage mammalian cell banks, ensuring their stability and consistency, and providing a secure supply for future manufacturing services.

Biologics Contract Development Manufacturing Organization – Market Overview

The biologics contract development manufacturing organization (CDMO) market has been rapidly growing in recent years. According to a report by MarketsandMarkets, the pharmaceutical contract manufacturing market size is projected to reach USD 258.3 billion by 2028. From 2023 to 2028, the is expected to grow at a CAGR of 7.9 %.

According to this study, the considerable growth of this market is mainly caused by high amount of drugs currently in the process of development and research, the considerable cost related to drug development in-house, and the technological achievements in this field.1

As for today, North America is estimated to have the largest CDMO market. While this is predicted to remain unchanged within the investigated period, the Asia Pacific market is expected to grow fastest, with an CAGR of 9 %.1

Recombinant antibody expression at evitria

evitria provides high-quality recombinant antibody expression services to the biotech and biopharmaceutical industry. These services are based on using mammalian expression systems. Along with the expertise of the team of professionals, they enable us to produce high-quality recombinant antibodies for research, diagnostic, and therapeutic applications.

With client’s input, we will design a custom process to optimize the yield, quality, and purity of recombinant antibodies in high speed. These processes follow strict quality control procedures to ensure that they are compliant with cGMP regulations.

With evitria, you can profit from the benefits of outsourcing recombinant antibody expression in order to entirely focus on the core challenges of your project.

- 1.Pharmaceutical Contract Manufacturing Market by Service (Pharmaceutical (API, FDF – Tablet, Capsule, INjectable)), Biologic (API, FDF, Drug Development), End User (Big Pharma, Small & Medium-sized Pharma, Generic Pharma) – Global Forecast to 2028. MarketsandMarkets. https://www.marketsandmarkets.com/Market-Reports/pharmaceutical-contract-manufacturing-market-201524381.html